CUSTOMER

Fugro operates a fleet of five survey essels that provide comprehensive Geophysical/hydrographic and Geoscience surveys. The company also offers precise navigation and positioning services for the offshore oil and gas industry.

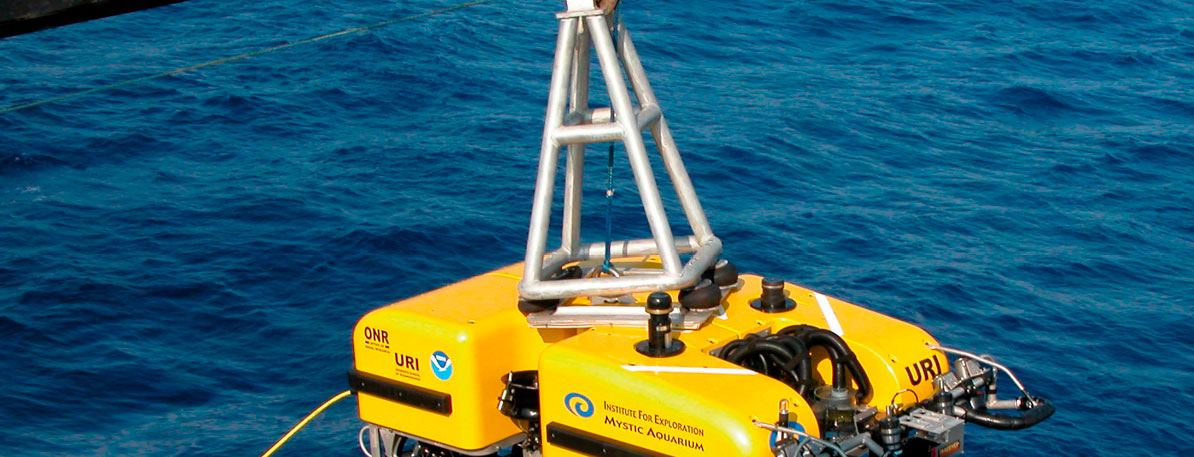

Fugro specialise in providing ROV support vessels, ROVs, trenching systems and remote engineering services to clients in the geographical region of the North Sea, Mediterranean and West Africa.

APPLICATION DETAILS

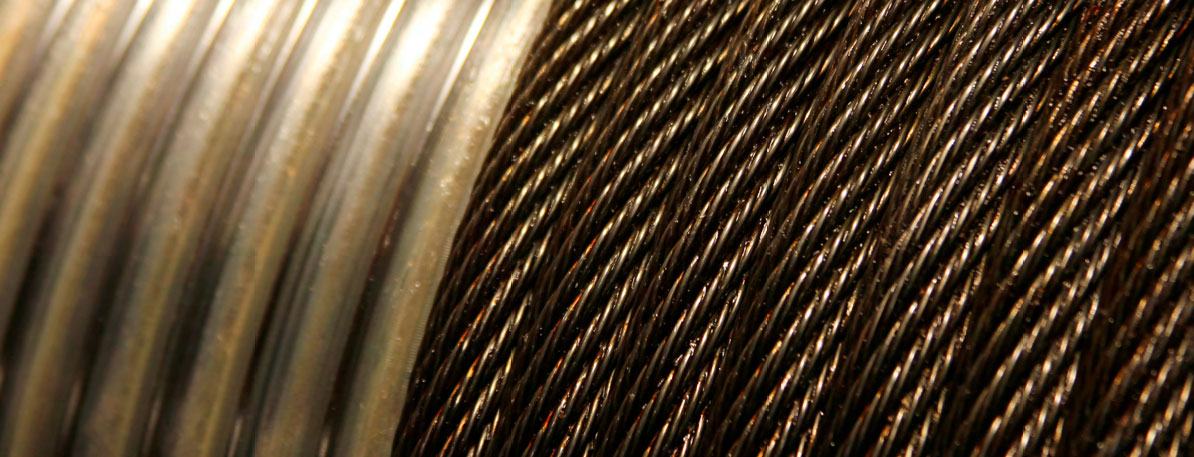

Fugro use armoured umbilical’s to tow, and deploy to the seabed, state-of-the-art subsea surveying equipment and sensors. The wire ropes need to be well lubricated and protected from the harsh operating conditions. Any dressing or lubricants used on the umbilical’s must have a low environmental impact.

ROV Umbilical’s require a lubricant to penetrate, resist against corrosion and provide good anti wear properties and when working in sensitive areas reduce any environmental impact.

BENEFITS & COST SAVINGS

Fugro decided to use the BIOGEN WIRESHIELD as it has a unique Pseudoplastic Rheology allowing great penetration into the wire ropes. The excellent anti-corrosion protection gives extended life reducing premature rope failure and as it is biodegradable with low eco-toxicity, allowing Fugro to work in environmentally sensitive areas.

CUSTOMER FEEDBACK

“We have been using WIRESHIELD for a number of years and are very happy with the performance of the product. Having now changed to the BIOGEN WIRESHIELD we feel very confident that we have not compromised on performance but have an additional benefit that we have minimised our environmental impact using biodegradable lubricants on the Umbilical’s.”

Andrew Morton – Technical Support Engineer

“BIOGEN WIRESHIELD has been very successful on our application. We had concerns that the outer armour on our umbilical’s are so tightly wound that the lubricant would not penetrate into the lower layer. However, this does not seem to be the case and certainly on one umbilical that we checked the lubricant certainly had penetrated through the 11.4mm Rochester armoured coax.”

Roy Fowler – Senior Operations Engineer